Unlike conventional aluminum composite panels for framed doors, expanded polyethylene (black) is used as the core material and the aluminum surface material is as thin as possible to minimize weight. Excellent workability makes them easy to cut and drill. Twelve types are available for various aluminum frame materials.

| Product Categories | Processed Products > Metal-Polymer Composite Boards |

|---|---|

| Main Applications | Daily Living > Housing and construction materials |

| Main ingredients | Al (aluminum) |

| Shape | Sheets |

| Features |

Features |

Color Ace Construction Material Series Specifications Chart

Figure in parentheses indicates quantity in package

| Grade and Standard | Thickness | Standard Size (mm) (weight per sheet) | ||

|---|---|---|---|---|

|

910×1820 |

1000×2000 (4.7 kg per sheet) |

1210×2420 (7.4 kg per sheet) |

||

| C222FF Glossy Silver | 3mm | (10) | (6) | (5) |

| C211FF Matte Silver | (10) | (6) | (5) | |

| C203FF Bronze | (10) | (6) | (5) | |

| C204FF Dark Bronze | (10) | - | - | |

| C206FF White | (10) | (6) | - | |

| C215FF Off-White | (10) | (6) | (5) | |

| C225FF Brown | (10) | - | - | |

| C237FF Black | (10) | (6) | (5) | |

| C290FF Metallic Beige | (10) | - | - | |

| C240FF Metallic Silver-Beige | (10) | (6) | (5) | |

| C242FF YK brown | (10) | - | - | |

| C211L-F Silver Ribbed | (10) | - | - | |

Color Ace Perforated Panel Specifications Chart

| Standard Thickness/Size (mm) | 3×1000×2000 |

|---|---|

| Standard Hole Diameters | 5 mm dia. 10P ( 60 deg. staggered pattern ) with 22.6 % hole area or 5 mm dia. 15P ( 45 deg. staggered pattern ) with 17.4 % hole area |

| Standard Colors | C211FF ( matte silver ), C203FF ( bronze ), C237FF ( black ), C215FF ( off-white ), or C240FF ( metallic silver-beige ) |

| Note |

|

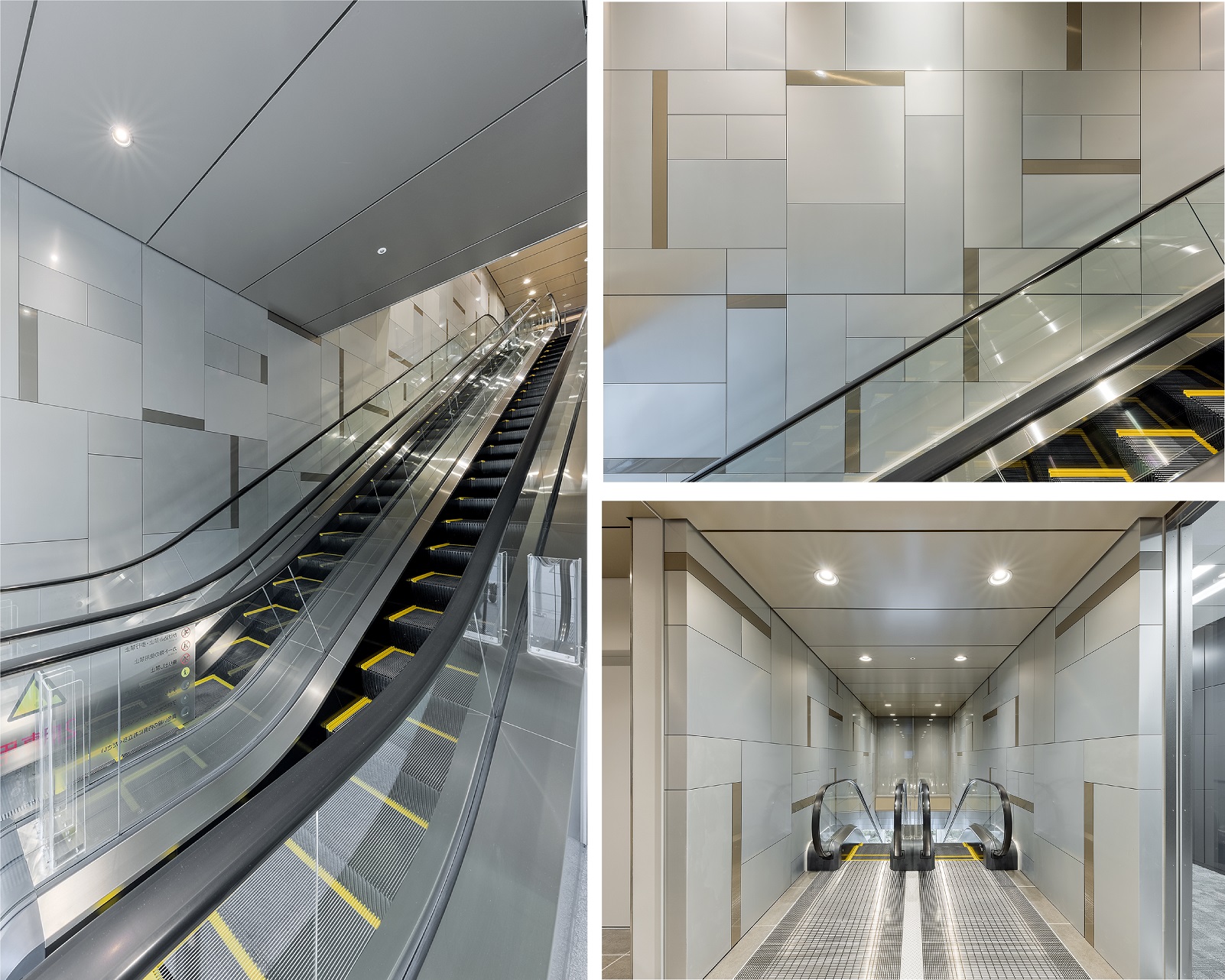

Color Ace Construction Material Panel Construction Example