FUKUDA has developed a metal powder for use in additive manufacturing deposition.

Powders for Additive Manufacturing Deposition

Additive Manufacturing Deposition Method

Additive manufacturing (AM) is a fourth processing method that is different from cutting, assembling, and casting. There are the following methods for AM that directly melts and solidifies metal powder.

- Laser Beam Powder Bed Fusion (LB-PBF).

- Electron Beam Powder Bed Fusion (EB-PBF).

- Directed Energy Deposition (DED).

AM can produce the following structures that cannot be produced by the conventional method.

- Reproduce the results of complex simulations.

- Special metallographic structure obtained at high cooling rate.

3D-CAD and LB-PBF (Laser Beam-Powder Bed Fusion) modeling (model provided by Metal Technology Co., Ltd.)

Example Using Example Using Additive Manufacturing Technology

Aging temperature and hardness of Cu-Cr alloy

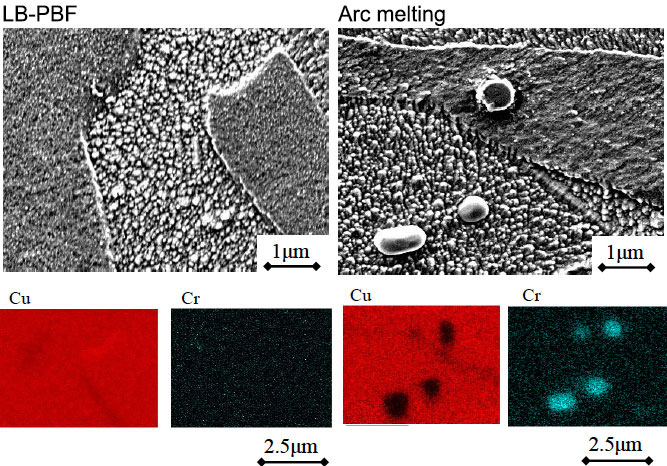

Cr solid solution state of Cu-1.0Cr alloy (FE-SEM / EDS)

AM has a high cooling rate and can obtain a metal structure that is difficult to prepare by the conventional method. Therefore, it is possible to manufacture Cu alloy parts having higher mechanical properties and electrical conductivity than the conventional method.

Development of powder for AM

Appearance of AM machine [SLM280HL]

(Manufactured by SLM Solutions)

Maximum laser output: 700W + 1kW

We model and evaluate using the prototype powder.

We provide powders that meet the needs of our customers.

Please contact us regarding composition and particle size.

Publications Related to Additive Manufacturing

| 2022 |

|

|---|---|

| 2021 |

|

| 2020 |

|

| 2019 |

|

| 2018 |

|

Inquiries and requests for small samples are welcome.